Aluminum Casting Cores

During the aluminum casting process, a core is inserted into a mold to shape the interior of the aluminum casting. For example, a hole that runs horizontally or vertically through a casting. Longview Brass and Aluminum has the capability to produce cores that satisfy a broad range of customer needs.

LBA is able to produce two types of cores:

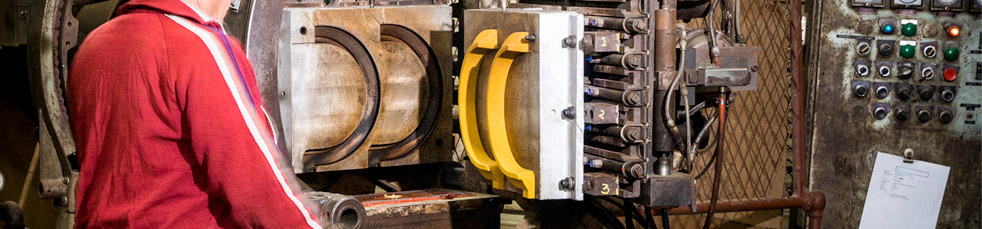

Shell Cores - the most efficient and economical way to use cores with sand casting molds. Shell cores are long lasting and can be used for several months of production. Longview Brass and Aluminum makes shell cores utilizing our five core machines and versatility is the key to our Core Room work.

No-bake Cores - made by mixing sand with a chemical binder/catalyst system and are also expendable. These cores are used for specialized jobs, such as large castings or short production runs, depending on the client’s needs. No-bake cores require a greater financial investment to produce than shell cores.